Quality Control

Quality Control

Quality assurance begins at Feilong right from the development of suppliers and their respective raw materials and continues with modern production process control measures & techniques, & finished goods inspection.

Raw material control:

Every batch of raw material strictly carry out sampling inspection, including humidity testing, density testing, chemical composition, etc.

Production Control:

Mixing: Computer-controlled automatic batching system; Multiple error-preventing design.

Forming: 630Tons Hydraulic press auto control by PLC, advance molds instruction with stable temperature and pressure control.

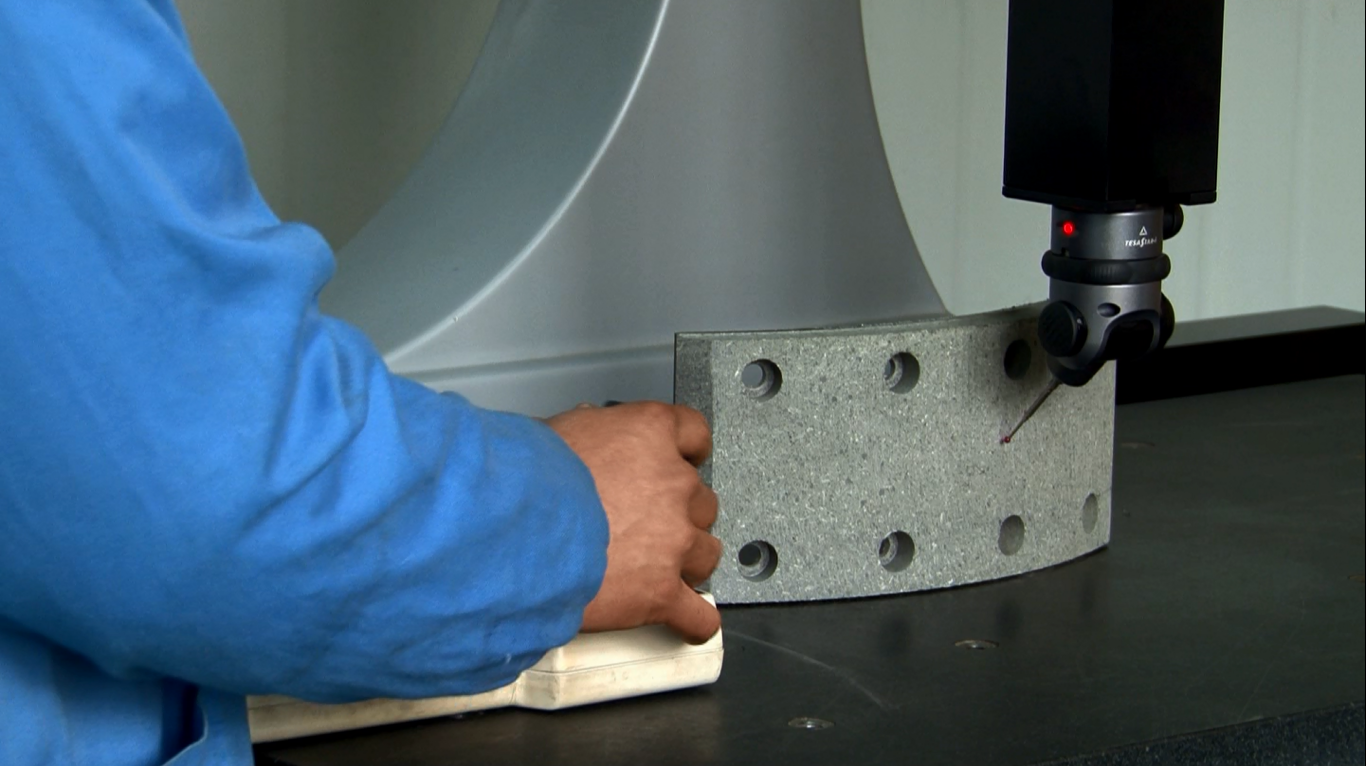

100% finished product inspection.

Traceability of product:

We consider Quality management as a key significant factor for long term success and growth of a company. We strive to achieve perfection in every process and to produce premium quality friction consistently.

All the goods can be traced back to batch of raw materials and finished product in order to guarantee the 100% top quality.

R&D Equipment:

Dyno(1:1 ) for passenger and commercial vehicles;

KRAUSS test machine for EU standard, Link Chase Test Machine;

XDMSM constant speed Tester, Sheartest Machine;

Universal strength tester, Hardness test, Salt spray test, etc.

Certifications:

Quality has been a ceaseless voyage at Feilong. We have continually been thriving ourselves to meet international quality standards. We have the best manufacturing and testing facilities across China.

Our certifications include ISO 9001:2008, IATF16949:2016, ISO 14001, OHSAS 18001-2007 guaranteeing highest level of compliance to quality and defect prevention. Our constant endeavor is to provide technological expertise and enhance ‘Customer Experience’.

We shall produce quality products in a safe and clean workplace by adopting and implementing an integrated quality, environment, occupational health and safety management system.