Air disc brake structure and maintenance introduction

What is the structure of the air disc brake? How to maintain air disc brakes? Let's take a look at the structure and maintenance of air disc brakes.

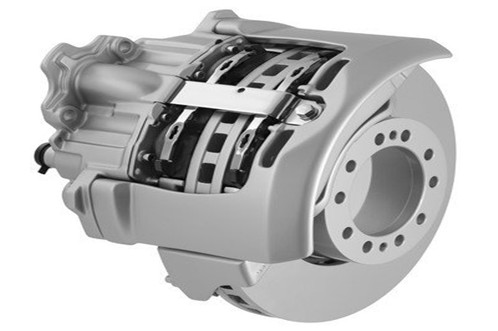

Introduction to the structure of the air disc brake

Air disc brakes are mainly composed of brake discs, cylinders, brake calipers, oil pipes and other components, and liquid power source. The air disc brake is a friction pair of the end surface of the rotating brake disc, and a brake block composed of a friction material and a metal base plate is mounted on the fixed bracket, and the brake block and the tensioning device thereof are mounted. In the clamping clamp brackets that straddle the sides of the brake disc, they are called brake calipers. The brake disc is made of an alloy that is just built and fixed to the wheel and rotates with the wheel. The cylinder is fixed on the bottom plate of the brake. The two friction plates on the brake caliper are mounted on both sides of the brake disc. The piston of the cylinder (air chamber) is pressed by the liquid (gas) pressure from the oil (gas) tube, and the friction plate is pressed against the brake disc to generate frictional braking, just like clamping the rotating plate with pliers, forcing the movement. The institution stopped moving.

Maintenance of air disc brakes

1. Keep the air disc brake assembly, especially the brake disc and brake lining surface clean, so that the entire air disc brake can be used freely, flexibly and reliably, and clean.

2. Regularly check (usually above the driving distance) the thickness of the brake disc. The brake disc must be replaced when the thickness of the brake disc after wear is less than the specified value.

3. Always observe the stock of brake fluid in the oil pool. When the liquid level is lower than the marking line, the original brand brake fluid should be added in time to make it higher than the mark line. Never mix other brands of brake fluid. After the addition is completed, the venting nozzle should be opened and then tightened.

4. When the oil is leaking from the piston of the main pump and the sub-pump, the seal must be replaced. Special attention should be paid to the fact that the new seal must be soaked in the brake fluid for more than a few hours before being replaced. When cleaning the cylinder or piston, the solution must be used and no petrol or other mineral oil is allowed.

5. In use, the surface of the brake lining is not allowed to be greased or brake fluid, and the thickness of the lining is checked regularly. When the thickness is less than the specified value, the dynamic lining should be replaced.

The above is about the structure and maintenance of the air disc brakes. I hope everyone can understand the structure and maintenance of the air disc brakes.