Which is the best for ceramic, semi-metal and asbestos brake pads

With the rapid development of technology, brake pads are also rapidly updated, from asbestos to semi-metal to ceramic fiber brake pads, so which one is the best? The following small series for everyone to explain in detail these three brake pads, I hope to help everyone.

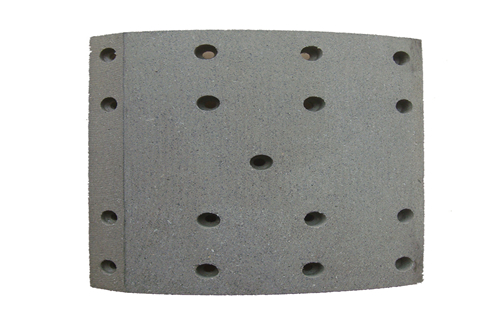

The main part of the brake pad is the lining piece, which is often called the friction material block. The first generation of the brake pad is the asbestos brake pad. The main component of the friction material is asbestos, and the asbestos is not environmentally friendly and has poor thermal conductivity. Most of the formulas now no longer contain asbestos. However, because of the low production cost and light weight, many car manufacturers still use asbestos-containing brake pads when producing commercial vehicles such as trucks and construction vehicles.

The second generation of brake pads are semi-metallic brake pads, mainly made of iron powder and rough steel wool as friction fibers. The thermal conductivity is better, the brakes are more powerful, and the brake failure does not occur at high temperatures. The disadvantage is that the brake comfort is not enough, the wear on the disc and the caliper is large, the brake will generate a large noise, and the brake effect will be weakened when a certain high temperature is reached.

In contrast, the third-generation metal-free brake pads have better braking effects than semi-metals, and are less prone to sound and do not hurt the disk. The disadvantage is that it is not wear resistant. Less metal is a small amount of iron, usually steel wool, so its production cost is slightly higher than that of semi-metal brake pads.

The fourth generation of ceramic brake pads subverts the traditional concept of ceramic brakes. Ceramic brake pads are composed of ceramic fibers, iron-free filler materials, adhesives and a small amount of metal. Compared with the previous semi-metal and metal-free brake pads, the advantages of ceramic brake pads are: 1. Thermal decay is small. In continuous braking, when the temperature is as high as 500-600 degrees, the brake pads are not deformed or melted, and there is still excellent braking performance. It is manifested in a large braking torque and a short braking distance. 2. Long service life. It has an average service life of more than 50% than that of semi-metal brake pads. 3. The damage to the dual part is small. The brake pads have a long service life in the pair (brake disc) and are more than 20% longer than the semi-metal brake pads. 4. Low noise. In the wading state and the state of the salt water road, there is no squeaking when braking, and the braking performance is good.

So is this the best for ceramic brake pads?

The 'good' here depends on which aspect. The best formula for one model may not be suitable for other models. The best brake materials are the size of the car and the car, the car usage, and the customer's expectations for checking brake performance, pedal feel, noise, and lining life. In short: no friction material formula is the best for all models.

After the above introduction, I believe that everyone should have an answer to ceramic, semi-metal, asbestos brake pads. In fact, no matter which kind of brake pads, only the brake pads that are most suitable for your car are the best. If you have any other questions about the brake pads, you can consult us.