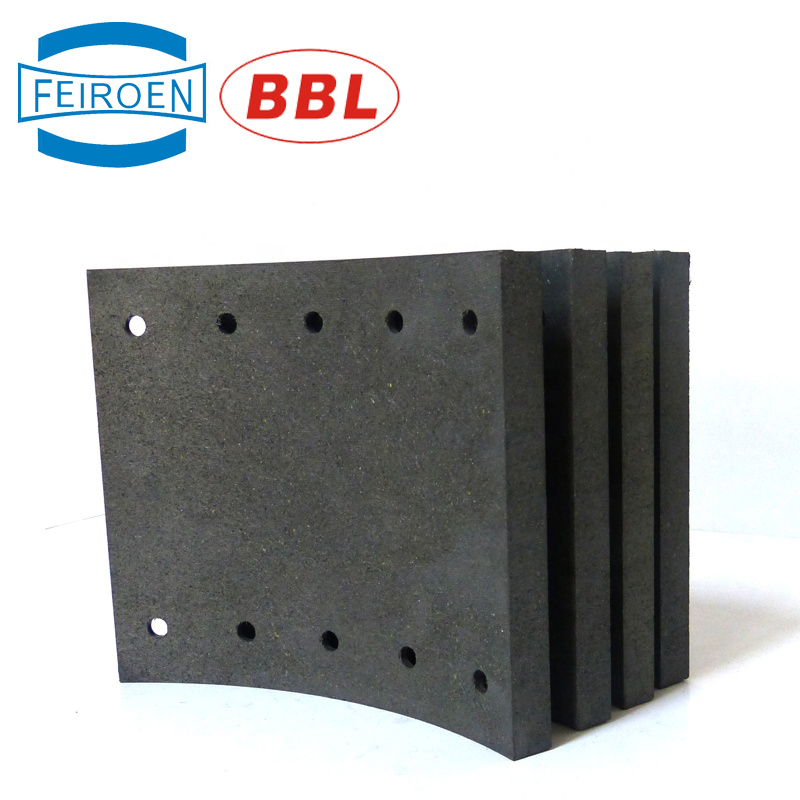

Brake Lining 19487

Brand FEIROEN

Product origin ZAOYANG

Delivery time 25 DAYS

As a professional brake lining manufacturer, We will continue to supply customers with quality and performance brake products. Among them, WVA19487 is one of The highest performance products, The detailed as follows:

100% Non-asbestos

* low noise and dustproof

*silent brake action.

* less fading and heat resistant up to 400° C

*sharp and safe braking performance.

*excellent friction performance and stopping power, Allow for sensitive braking

Download

WVA No.: WVA19487 ; WVA 19495

BMFC : MP/32/1; MP/32/2

OE No. : 315.1287.0/ 346 423 96 10 / 81502006752 / 81502200505 / 3464230710 / 3464232910 / 6174231211 / 0345-065 / 81.50220.0283 / 81.50221.0951

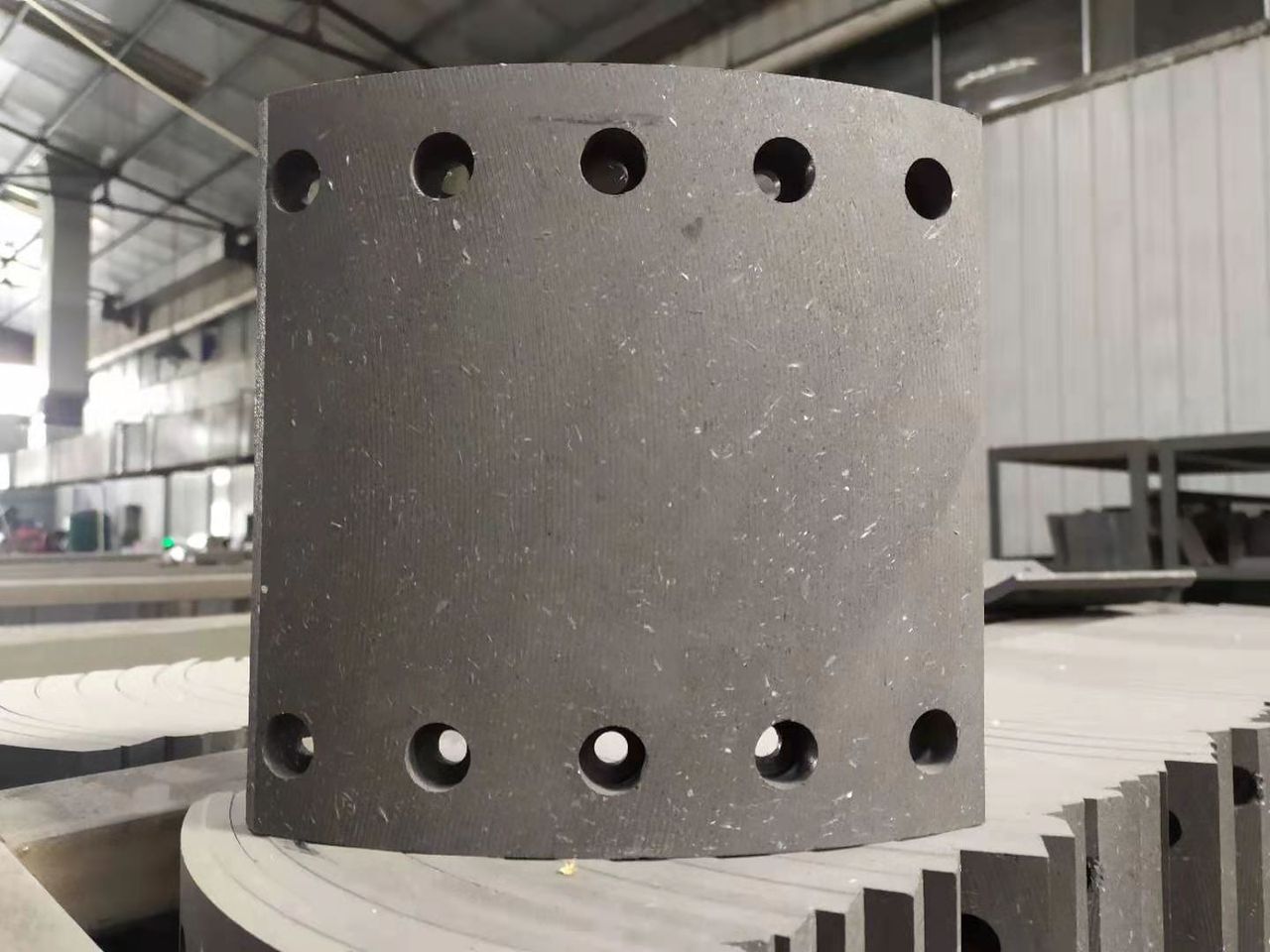

Dimension (inner arc length×width×thickness): 178×183×12.8/16.9

Drum DiameterØ: 410

Application: MERCEDES,Renault-Saviem, Steyr,Van Hool,MAN

Products Features

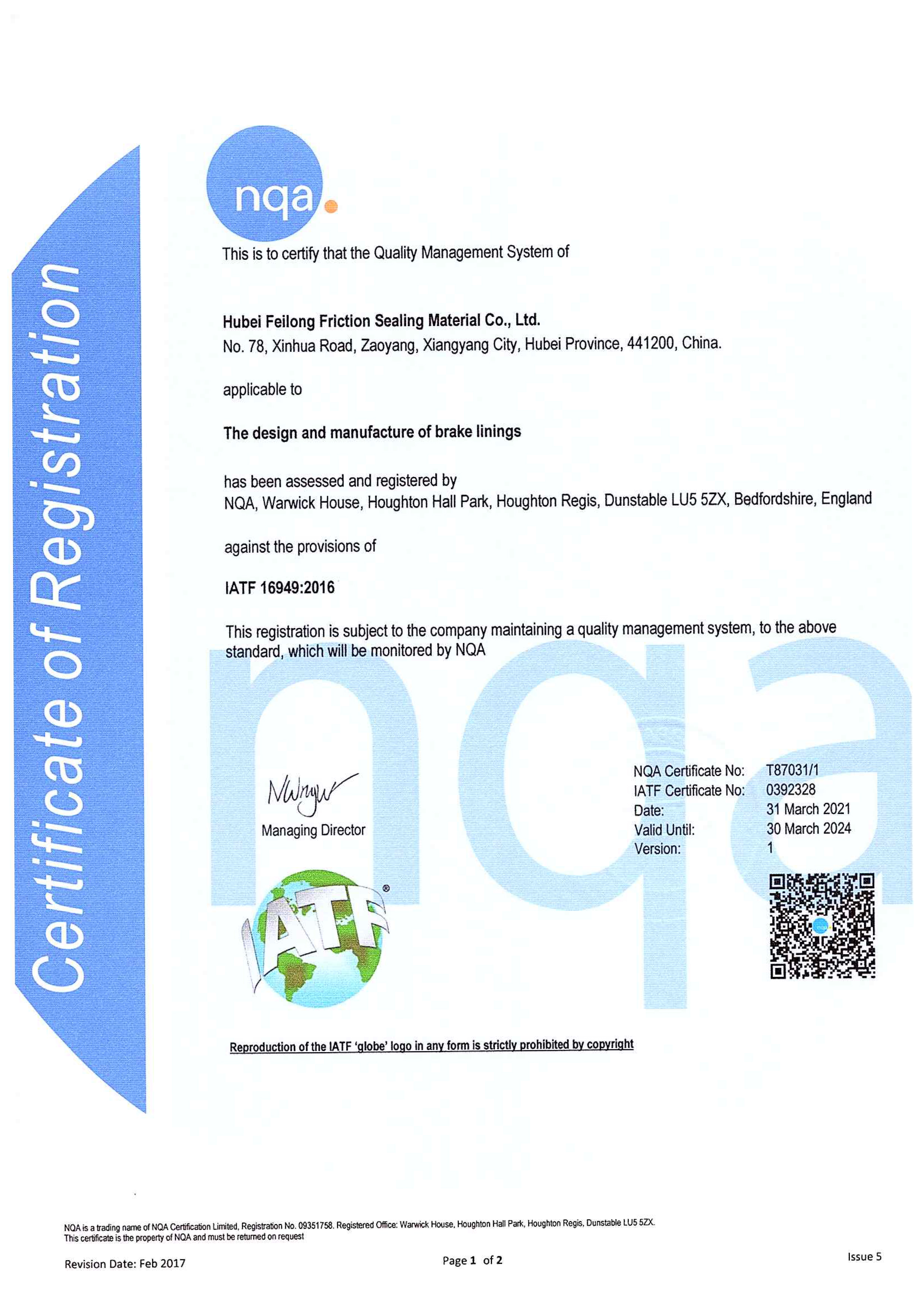

(1) Material: Low metalic, NAO, 100% non-asbestos.Tested and approved to UN ECE R90:02 by the Kraftfahrt-Bundesamt & IDIADA and is manufactured in state of the art production facilities accredited to ISO9001 and TS16949.

(2) Certification: EMARK (E1), ISO14001:2015, OHSAS18001:2007, IATF16949:2016

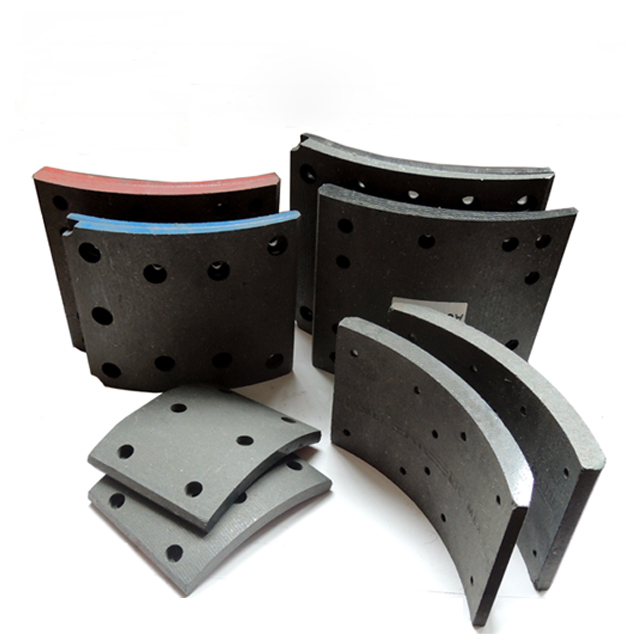

(3) Color: black/gray/green, or as customer's request

(4) Accessories: Reviets( steal or other material as required)

(5) Standard Export Package: Plastic Bag Shrinked+Neutral/brand box (white, Feiroen box or customer's color box)+ Pallet

(6) Gurantee:80000-100000km

(7) Minimum order quantity: 50sets

(8) Delivery time: 35-40days

(9) Advanced technical design ability and excellent test equipments to satisfy material design for different markets.Long service Life, wear-resistance, good braking performance,safe,environmental protection

(10) Production Base : Hubei province,China

Four breakthroughs

1. New super high temperature resistant (-50 ° C - 500 ° C) elastomer is added to effectively control material noise.

2. The carbon component is added to greatly increase the strength and stability of the material, reducing wear and attack on the friction pair.

3. Strengthen the application of precious metal sulfides to control the thermal decay of materials.

4. The ultra-fine zirconium salt was replaced as a friction-increasing material, so that the material has better friction performance and stability.