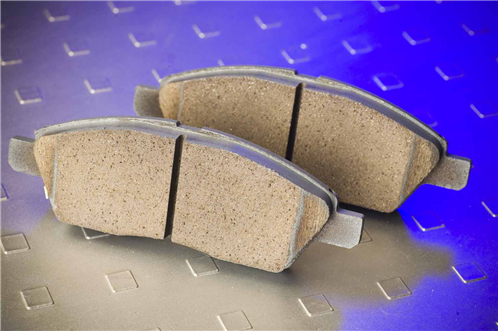

D1108 Brake Pads

Brand Feilong

Product origin China

Delivery time 30 days

Supply capacity 30000 sets/month

> 100% NON-ASBESTOS MATERIAL

> PREMIUM QUALITY BRAKE PADS

> BEST STOPPING POWER IN A WIDE VARIETY OF ROAD CONDITIONS

>ENGINEERED FOR QUIET BRAKEING

> LOW DUSTING FOR CLENER WHEELS

> O.E.M MATCHED FRICTION DESIGN

> HIGH-TEMPERATURE HAVE GOOD BRAKE

Most of the kinetic energy of an automobile brake needs to be quickly absorbed by the friction pair (a system of objects moving against friction), and this part of the energy is quickly converted into frictional heat, which causes the temperature of the brake to rise rapidly. The maximum temperature reached depends on the time and severity of the brake and the ability of the brake system to dissipate heat. At this time, the brake lining is in the range of 200-400 °C.

The wear phenomenon of the brake lining during use reflects the mechanism of having two interface features at the same time. Possible wear mechanisms are thermal wear, abrasive wear, adhesive-tear wear, fatigue wear, and macro shear wear.

Of particular note is thermal wear because it contains many physicochemical reactions in which chemical bonds break continuously. These physicochemical reactions may include thermal decomposition, oxidation, granulation, explosion, melting, evaporation (sublimation), and the like. The rate at which they occur increases exponentially with temperature. Thermal decomposition mainly occurs in the center of the friction lining, and the degree of edge and angle is slightly lighter, while the oxidation reaction mainly occurs at the sides and corners.

Abrasive wear is caused by the ploughing and wear debris of the wear debris and foreign particles. The cause of thermal fatigue is that repeated heating and cooling cause periodic stresses and large temperature changes in the surface material. Macro-shear wear is a sudden failure of a friction material that has been weakened by heat, and it is most likely to occur with temperature rise and severe braking.

In principle, the frictional heat is quickly dissipated and all of these wear can be controlled or minimized.

Do you know these problems with brake pads?

1. What is the noise of the brake pads?

The noise is mainly the frequency resonance. If the natural frequencies of the two materials or components themselves are the same, resonance is easy to occur. The brake pad alone solves the noise is very simple, the service life is simple to solve alone, and it is very simple to solve the disc alone. There are many factors in the noise generation. The whole brake assembly system is the cause of noise. The improper selection of the brake disc and the serious wear of the disc will cause noise. In many cases, everyone has wronged the brake pads.

2. Is the ceramic fiber added to the formula a ceramic formula?

No. Ceramic fiber is only one of the commonly used fibers for brake pads, as well as metal fiber, mineral fiber, wood fiber, aramid fiber, etc. Their role is to connect various fillers, just like when adding rural mud walls. Straw is the same.

3. Why are some grooves on the plate ground? Is the brake pad very hard?

The hardness of the brake pads is standard, basically between 30 and 70 Shore hardness. This hardness is not the main cause of wear on your brake discs. The grinding agent in the brake pads is the main component of the wear plate. The soft and hard brake pads are not the cause of the serious wear of the disc. The culprit is the low-cost grinding agent.

4. If the metal content is too much, it will be harder.

Not right. Many of these statements are the auto repair factory's statement and are not scientific. The original car on the original car is mainly a semi-metal formula, which contains a lot of metal. Have you heard a lot of noise? Noise is not directly related to soft and hard. The grinding disc and noise only indicate that the product formula is not mature, and has nothing to do with metal.

In fact, the metal material is mainly used to connect filler and heat conduction in the formulation. At the same time, their hardness and disc are not much different, and will not cause great wear on the disc. The real grinding disc and the increase of braking capacity are not for you. These metals, but the abrasive fillers that you can't see are harder than the brake discs, they are actually emery, and they are similar materials to your common sandpaper and grinding wheels.