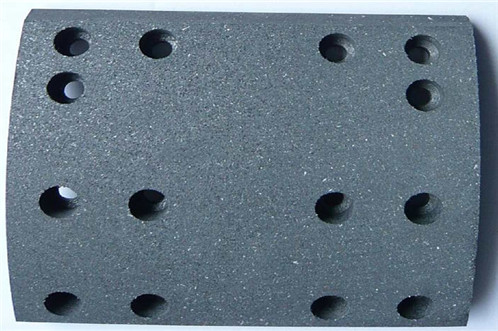

D1212 Brake Pads

Brand Feilong

Product origin China

Delivery time 30 days

Supply capacity 30000 sets/month

> 100% NON-ASBESTOS MATERIAL

> PREMIUM QUALITY BRAKE PADS

> BEST STOPPING POWER IN A WIDE VARIETY OF ROAD CONDITIONS

> ENGINEERED FOR QUIET BRAKEING

> LOW DUSTING FOR CLENER WHEELS

> O.E.M MATCHED FRICTION DESIGN

> HIGH-TEMPERATURE HAVE GOOD BRAKE

Material: Semi-metal ,Low metalic, Ceramic, 100% non-asbestos

Color: black/gray/green, or as customer's request

Certification: TS16949

Accessories: Shims+ sensors+cliper+other accessories

Gurantee:No noise,No dust,servic-life can rearch 30000-50000KM

Best stopping power in a wide variety of road conditions

Drum brake pad

According to the connection between the brake pad and the brake shoe, the drum brake pad can be divided into two types: riveted type and bonded type. The riveted brake pads can withstand large braking loads and are not as demanding as disc brake pads for reducing and overcoming noise. They are mainly used for medium and heavy duty trucks. Produced by the wet process before the 1960s, the process is relatively backward. After the 1970s, most of them were produced by dry process. The bonded drum type brake pad has a smaller braking load than the riveted type, and is mainly used for cars and light type cars, and is mostly produced by a dry process.

Disc brake pad

Disc brake pads are mostly produced in a dry process, mainly used in cars. They are characterized by a small area and can withstand high braking loads, and have the highest performance requirements in various types of automotive brake friction materials. Therefore, the friction of the disc brake is better than that of the drum brake. When the brake is continuously applied, the brake is not deteriorated and the brake is disabled.

Ceramic brake pad

Our brake pads are made in a dry process. The products use a dry one-shot hot pressing process: through the use of powdered resin, inorganic fibers, organic fibers and other various fillers are directly dry-mixed and then hot-pressed into products. Its characteristics are: mature technology, good stability, high strength and stable quality.

The company introduces foreign brake pad complete production equipment and advanced manufacturing excellent technology, and has independent research and development laboratories. After drafting the enterprise standard higher than the national standard, it selects various high-standard raw materials (such as imported mineral fiber from the Netherlands, extremely low slag). Ball content; soft thermal conductive materials, high-performance imported aramid and standard German silencer technology silencer, etc.), after hundreds of thousands of R & D tests, and all passed, can be produced according to the highest standards of the industry.

10 years of focus on automotive ceramic brake pad manufacturers, the main products are the mainstream car ceramic brake pads on the market - no noise, low dust, comfortable braking, high performance formula.