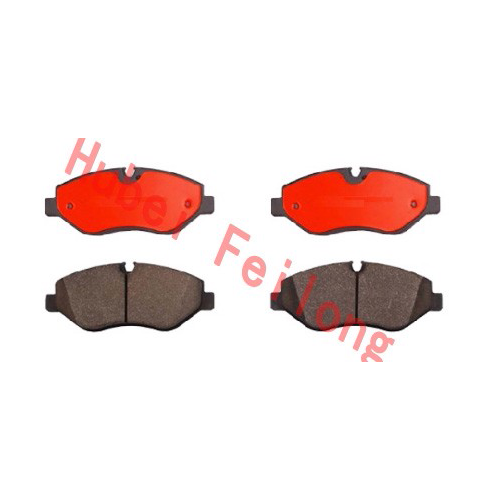

D1316 Brake Pads

Brand Feilong

Product origin China

Delivery time 30 days

Supply capacity 30000 sets/month

>100% NON-ASBESTOS MATERIAL

>PREMIUM QUALITY BRAKE PADS

>BEST STOPPING POWER IN A WIDE VARIETY OF ROAD CONDITIONS

>ENGINEERED FOR QUIET BRAKEING

>LOW DUSTING FOR CLENER WHEELS

>O.E.M MATCHED FRICTION DESIGN

>HIGH-TEMPERATURE HAVE GOOD BRAKE

Dustless brake pad packing

When the friction material is formulated, the filler must be used to understand the properties of the filler and the various properties of the friction material. Proper use of fillers determines the properties of the friction material and is also very important in the manufacturing process. According to the role of the friction property modifier in the friction material, it can be divided into two types: "grinding filler" and "wearing filler". The friction material itself is an abrasion resistance material, and has a high friction coefficient in order to perform braking and transmission functions, so the grinding filler is a main component of the friction performance modifier. The grinding action of different fillers is different.

The Mohs hardness of the grinding filler is usually from 3 to 9. The grinding effect with high hardness is remarkably obvious. 5.5 Fillers above hardness are hard fillers, but the amount and particle size should be controlled. The anti-friction filler is generally a low hardness material, lower than the Mohs hardness 2 mineral. Such as: graphite, molybdenum disulfide, talc, mica and so on. It reduces both the coefficient of friction and the wear of the dual material. Thereby increasing the service life of the friction material.

Friction materials are a special material that works in hot and high pressure environments. Therefore, it is required that the filler components used must have good heat resistance, that is, thermal stability, including thermochemical effects of thermophysical effects. The packing density of the filler has a great influence on the performance of the friction material. The different performance requirements of the friction material also have different requirements for the packing density of the filler.

Dustless brake pad fault judgment method

For a vehicle's brake failure, it may only be discovered when the brake is abnormal or the braking force is degraded. However, if these conditions occur in high-speed driving, etc., it is very dangerous. When we are driving, we pay more attention to some small "signs" and we can judge that there may be problems with the brake system.

First of all, the feeling of braking is very important. When the normal brake system brakes, it feels that the pedal is solid and the car should immediately stop in a straight line. When the vehicle has severe jitter or slanting to one side, or feels that the pedal response is not sensitive and soft, it should cause the owner to pay attention.

Secondly, there are some screams and abnormal sounds. Some screams are caused by the interaction of the brake pads with the gaskets on the back. A slight scream occurs when the brakes are not used at low speeds because of the brakes and the edges of the sheets.

Finally, if the brake temperature is too high, smoke and odor will appear, and the brakes will be noticeably soft, mostly due to the long-lasting use of the brake system.

Dustless brake pad formula verification method

After the selection of the excellent formula, repeat the test more than three times to verify the stability of the formulation performance. If the performance has been stabilized and meets the requirements, the scale of the trial can be expanded. Products are typically manufactured to specific dimensions. The main purpose is to verify the process passability of the formula on the one hand, and to determine the good process conditions; on the other hand, the 1:1 bench test, the whole vehicle test field test and the road test are performed on the manufactured products.

The bench test generally tests the manufactured products according to the set test procedures and evaluation methods that can simulate the actual use conditions. Since the bench test is time-consuming and costly, the number of tests should not be excessive. If the technical requirements are met, the formula can be basically shaped. At this time, it can be transferred to small batch trial production according to the basic shaping formula, and several products are selected for the whole vehicle test field and the actual loading road test. Sometimes the test field test and the road test are carried out by the user and completed.