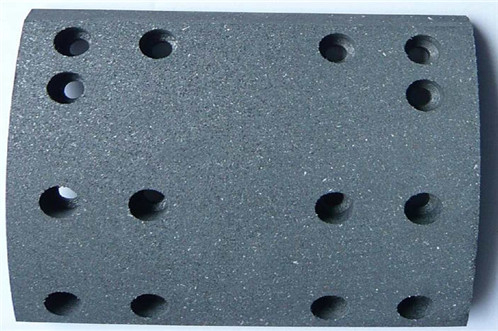

D340 Brake Pads

Brand Feilong

Product origin China

Delivery time 30 days

Supply capacity 30000 sets/month

> 100% NON-ASBESTOS MATERIAL

> PREMIUM QUALITY BRAKE PADS

> BEST STOPPING POWER IN A WIDE VARIETY OF ROAD CONDITIONS

>ENGINEERED FOR QUIET BRAKEING

> LOW DUSTING FOR CLENER WHEELS

> O.E.M MATCHED FRICTION DESIGN

> HIGH-TEMPERATURE HAVE GOOD BRAKE

Brake pad inspection

In daily life, many people know that the brake pads need to be replaced when there is a problem with abnormal brakes or braking. Then how to pre-test in the daily routine, replace the problematic brake pads in advance? Mainly by watching the thickness of the brake pads.

"Looking" means looking at the thickness. A new brake pad will gradually become thinner as it rubs continuously during use. Excellent technicians suggest that when the thickness of the brake pads is only about 1/3 of the original thickness (about 0.5 cm), the owner will increase the frequency of the self-test and be ready to replace it. Of course, due to the design of the wheel hub, individual models do not have the conditions for visual inspection, and it is necessary to disassemble the tires to complete. Generally, the brake pads will have alarms (some are alarm lines), which is the limit of brake pad replacement. If the thickness of the brake pads is parallel to this mark, it must be replaced.

Small suggestion: The brake pads are not strictly replaced according to the car environment and driving habits. Generally, it is necessary to consider replacing them after driving about 60,000 kilometers. When the naked eye observes that the brake pads are thin, they should be inspected by technicians during maintenance. Because there is an error in the naked eye observation, the repair station passes the caliper more rigorously than the naked eye.

What should I pay attention to when replacing the brake pads?

The brake pads of a car are a consumable part that needs to be replaced after a certain period of time or mileage. After the brake pads are replaced, the contact surfaces of the new brake pads and brake discs may not be very good, which may affect the braking performance of the car, and severe brake failure. The newly replaced brake pads need to be run-in, in order to better match the brake discs for better braking.

The newly replaced brake pads should be used as much as possible in the running-in, and try not to use the sudden braking during the running-in period. After the running-in brake pads still need to pass through a few hundred kilometers to achieve the desired effect, be sure to drive carefully to prevent accidents. For the method of running-in, first of all, it is not strictly required that every time you need a very accurate speed, you can start the brakes when you accelerate to about 60-80km/h. Secondly, when you brake to 10~20km/h, keep your eyes. Look at the road and make sure that the road is safe. It takes about ten braking steps.

Brake pad experiment

After the laboratory test, our brake pad formula is based on a series of data, after careful and effective analysis, comprehensive balance to select the appropriate formula. After the formulation was selected, the stability of the formulation performance was verified by repeating the test multiple times. Expand the scale of the test when performance has stabilized and meets the requirements. The product is manufactured according to the specific size required to verify the process passability of the formulation, and the process conditions are initially determined. In addition, a 1:1 bench test, a vehicle test field test and a road test are performed on the brake pad manufactured.

Bench testing is a very time consuming and expensive device. Feilong brake pad factory determines the formula by simulating actual use conditions through repeated bench tests. After the basic setting formula, it is transferred to a small amount of trial production, and the products are selected for the whole vehicle test field test and the actual loading road test. There is no end to the road, and Feilong is constantly challenging and perfecting itself. We only focus on one thing in our lifetime, that is, we strive to be a better manufacturer of ceramic brake pads in the country.