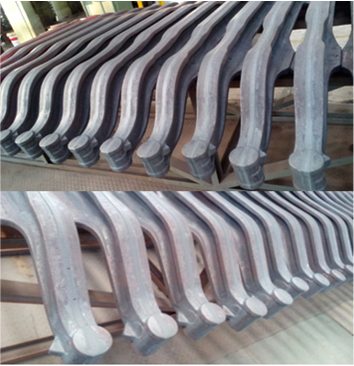

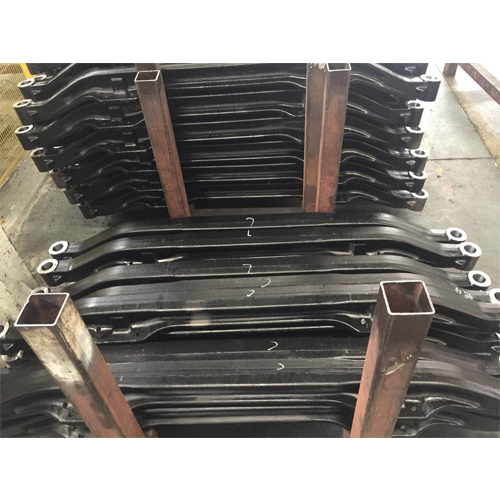

Deep Drop Front Axle

Brand BBL

Product origin China

Supply capacity 200,000pcs/year

High Strength

Fine Finish

High Precision

Bench Test Over 1 Million Times

Download

Low floor bus offers more convinient access for elders and handicapped passengers.

It is the future trend of bus manufacturing.

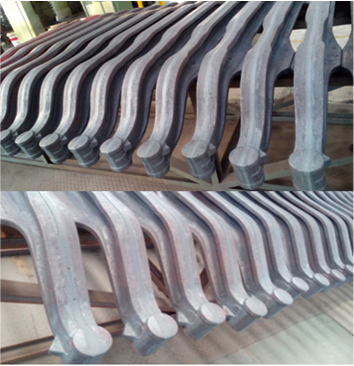

BBL high drop axle series are specially designed and forged to accomplish the deep fall distance between fist-shaped ends and leaf spring seat.

Product features.

Tire sizes from 17.5 to 24 inches

Axle loads from 3.5 to 9 tons (per axle)

Gross vehicle weight rating (GVWR) from 6.5 to 20 tons

Longer lifetime and easy maintenance

Optimum power/weight ratio due to weight-optimized technical design

Modular concept provides maximum flexibility to customer request

We use our customers’ experience, their requirements and demands as an essential precondition in the development and technology of new axle concepts.

Durability

Fuel efficiency

Quiet operation

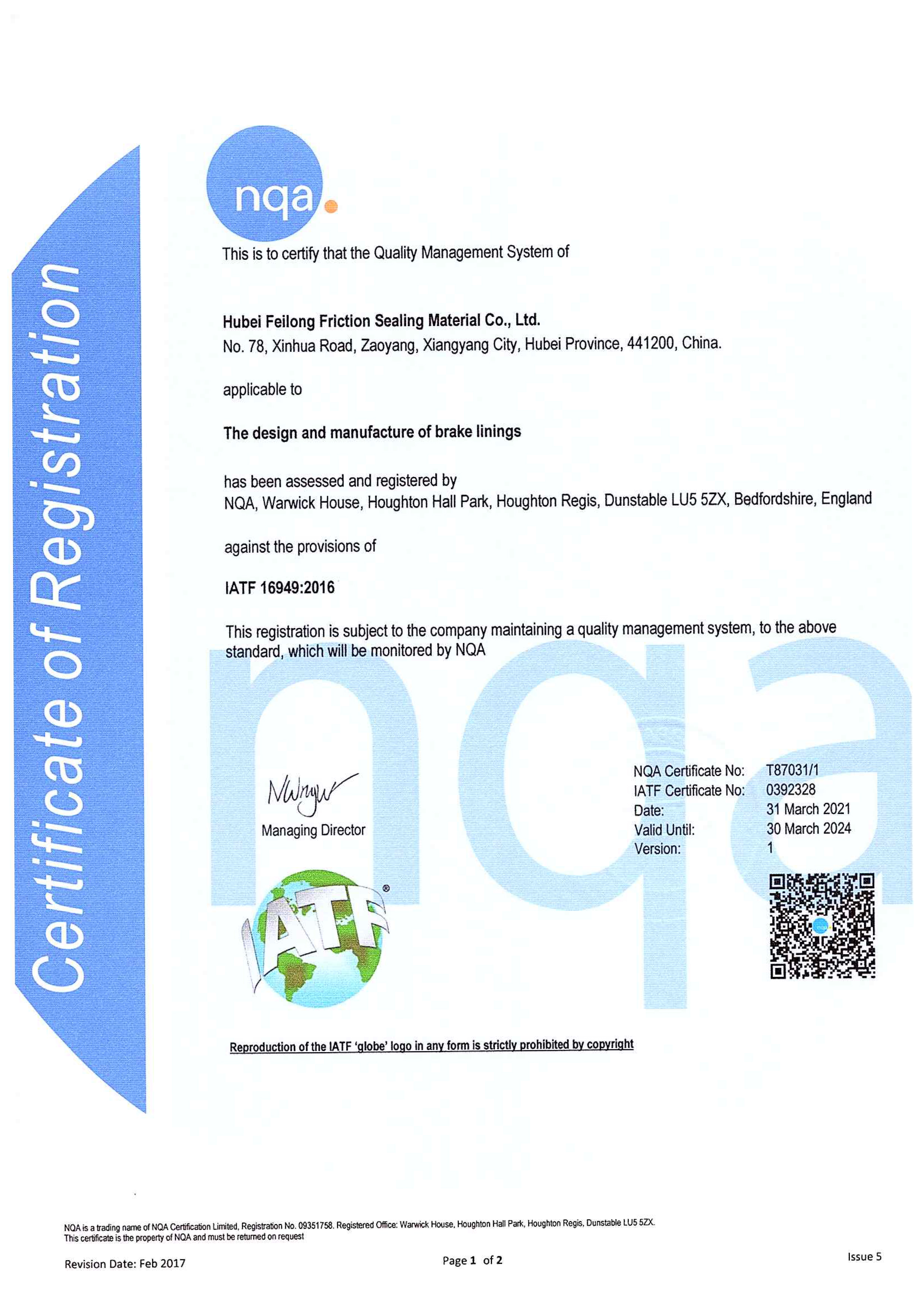

Top vehicle manufacturers around the world know they can depend on these features of our axles and the reliability of our services. BBL axle aims to be one of the world's best producers of commercial axle beams.

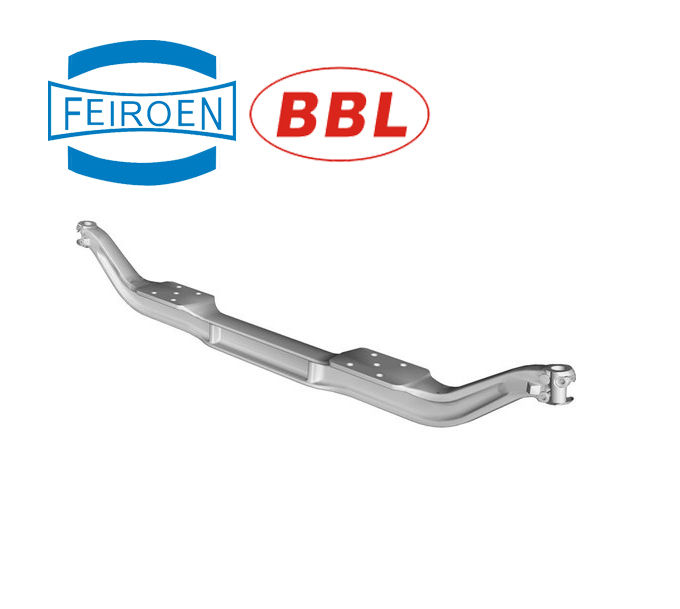

BBL axle beam is manufactured by high precision roll forging and die forging technology which is the most stable and matured technique today.

The 8000 ton double disk friction press is able to produce various types of axles on the market.

BBL front axle is supplied to famous domestic oe customers like JAC, Foton, CAMC and axle factories like YIHE ,Hande and Dongfeng Dana etc.