Trailer Trunnion Shaft

Brand BBL

Product origin China

Forging trunnion shaft is manufactured by BBL with high strength steel.

BBL trunnion shaft is able to be customized according to different specifications.

Life-time warranty is endowed.

Balance shaft function

The balance shaft is used to balance and reduce the vibration of the engine, thus reducing engine noise, extending service life and improving rider comfort. However, not all engines require a balance shaft, such as a "V" type and a horizontally opposed engine. These engines with well-balanced vibrations do not need to design a balance shaft; they also depend on the manufacturer's specifics for different brands and models. In the case, some engines that theoretically need to balance the shaft can't see him either.

Balance axis classification

There are two types of balance shafts for motorcycle engines: double balance shafts and single balance shafts. The two methods are the same in working principle, but the specific structure is different.

1. Double balance shaft mode

The double balance shaft adopts the chain transmission method to drive the two balance shafts to rotate. One of the balance shafts has the same speed as the engine, which can eliminate the first-order vibration of the engine. The other balance shaft rotates twice the engine speed, which can eliminate the engine. The second-order vibration can achieve the ideal damping effect. The double balance shaft method is more complicated, high in cost, and takes up a large space of the engine, and is generally used on a large displacement motorcycle.

There is also a double balance shaft arrangement, that is, the two balance shafts are arranged symmetrically with the center line of the cylinder, and the rotation direction is opposite, and the rotation speed is the same as the crankshaft rotation speed to balance the first-order reciprocating inertia force of the engine. For example, the balance shaft on the 276Q engine is arranged as above.

2. Single balance shaft mode

The single balance shaft adopts a single balance shaft and works by gear transmission. The balance shaft drive gear of the fixed connection is driven by the crankshaft rotation -> balance shaft driven gear -> balance shaft. The single balance can balance the first-order vibration that accounts for a considerable proportion of the entire vibration, which can significantly improve the vibration of the engine. Due to its simple structure and small footprint, the single balance shaft has a wide application in single-cylinder and small-displacement engines.

Balance Shaft/ Trunnion For Commercial Vehicles

The production lines are equipped with 2 sets of 8000 ton double disk friction presses, 4 sets of 1600 ton high power screw presses, 2 sets of roll-forging machines, 6 sets of KUKA robots, 2 heat treatment lines for quenching and tempering, 1 test line for fluorescent magnetic particle flaw detection, 1 paint line, 3 machining lines.

Each production line is equipped with 3 KUKA robots and one mechanic arm to ensure quality consistency. The hitting power of 8000 ton double disk friction press can reach 12,000 ton, we are able to manufacture all kinds of forgings.

Both numerical control equipment and KBK are used to ensure processing precision and high efficiency.

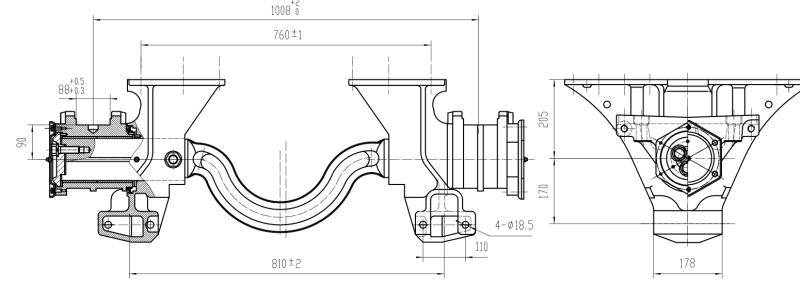

Trunnion shaft is a cylindrical protrusion used as a pivoting point for dual axles to keep each wheel running properly on the bumpy road. BBL forging trunnion provides high strength to meet the harsh working environment requirement.

Our balance shaft specifications can be customized to be equipped on different trucks.