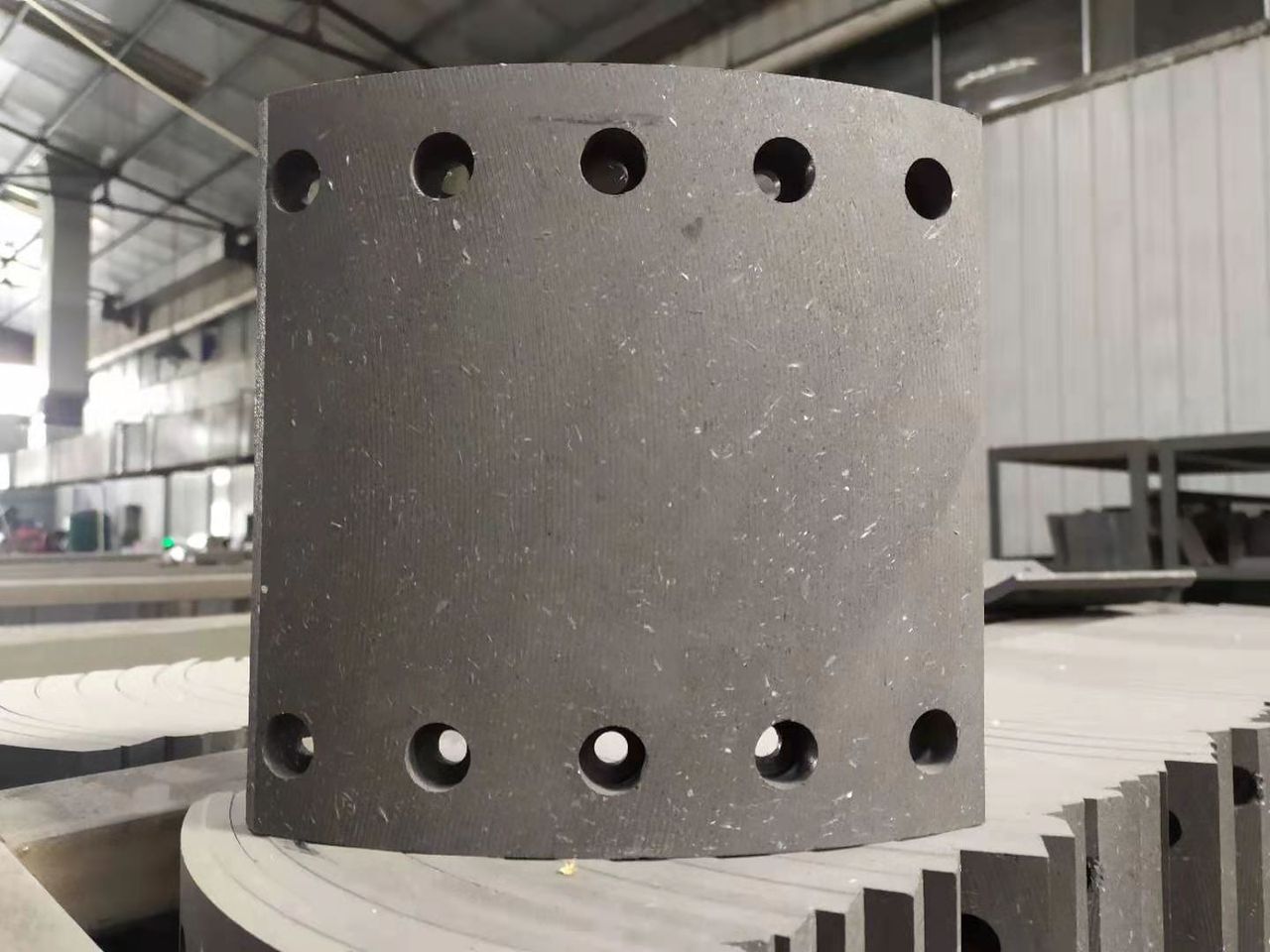

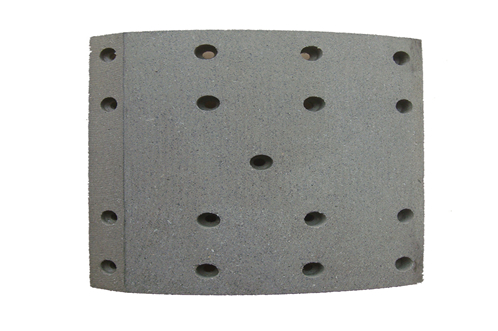

Brake Lining 1308

1. Guranttee: 150,000.00km ,wear-resistance high-ternperature resistance good braking performance long service life .

2. Certificate: TS16949 & ECE R90

3. Feiroen brake linings have been proven on truck, trailer, bus and coach applications to provide premium braking performance and durability under all service operating conditions.

4. Low noise

5. Consistent braking effort and pedal feel.

Item No: 1308 brake block.

BMFC No: 1308

Dimension (inner arc length×width×thickness): 393.5×101.2×10.7

Drum Diameter: wear-resistance high-ternperature resistance good braking performance long service life .

Car brake lining selection method

The braking system of the car is to make the driving car decelerate or even stop according to the driver's request; to make the stopped car stably park under various road conditions; and to make the speed of the downhill car stable. In the braking system of the car, the quality of the brake linings directly affects the braking effect of the car, so it is especially important to choose a good brake lining, which directly affects the driving safety of the owner.

At present, our common brake lining formulations mainly include semi-metal formula, less metal formula, NAO formula, ceramic formula and so on. There are many parameters for automotive brake linings, such as friction coefficient, shear strength, thermal decay resistance, etc., which are required to meet national standards. If you use a brake lining of poor quality, you may not be able to stop the car, the braking distance is too long, etc., which may cause traffic accidents. However, if the friction coefficient of the brake lining is too large, it is easy to cause the tire to lock when the car brakes, resulting in loss of control of the burning piece or the vehicle, which jeopardizes the safety of the driver. Therefore, we have to choose the brake lining products produced by regular manufacturers.

brake lining alarm

The brake linings of a car are wearing parts that are gradually consumed when we are driving daily. The effective use of the front brake linings of a typical vehicle is about 30,000 to 50,000 kilometers, which is slightly increased or decreased according to personal use habits. Because the driving in the urban area is relatively crowded, the brake lining loss is correspondingly large, and the sudden braking should be minimized when driving, so that the brake lining can obtain a longer service life.

At present, the common brakes on the vehicle are the brake lining alarm and the brake lining alarm line. The alarm line of the brake lining is connected with the brake warning light on the dashboard of the vehicle, and the warning light is illuminated as the judgment basis for replacing the brake lining. When the brake lining warning light is on, it is the last bottom line for replacing the brake lining. At this time, the brake lining has almost lost its function. The steel back of the brake lining will rub against the brake disc. If it is not replaced in time, the brake disc will be damaged. Here we recommend to replace the brake linings near the end of life, not just rely on warning lights to judge.

Advantages of ceramic materials

First, ceramic materials have good thermal stability and low thermal conductivity, and good wear resistance. The long-term use temperature is 1000 °C. This feature makes ceramics suitable for high performance requirements of various high performance brake materials, and can meet the technical requirements of high speed, safety and high wear resistance of brake linings.

Second, it has good mechanical strength and physical properties. Can withstand large pressure and shear forces. Before the assembly of the friction material, it is necessary to perform machining such as drilling and assembly to make the brake lining assembly. Therefore, the friction material must have sufficient mechanical strength to ensure that no damage or chipping occurs during processing or use.

Subsequently, the ceramic material has a very low thermal attenuation, ensuring that the vehicle has good braking performance to ensure safety, and the thermal attenuation of the brake lining is small to improve the performance of the brake lining. Due to the fast heat dissipation of the ceramic material, the friction coefficient of the brake lining is higher than that of the metal brake lining.