Brake Lining 19938

Brand FEIROEN

Product origin ZAOYANG

Delivery time 30 DAYS

* low noise and dustproof

* silent brake action.

* less fading and heat resistant up to 400° C

* sharp and safe braking performance.

* excellent friction performance and stopping power, Allow for sensitive braking

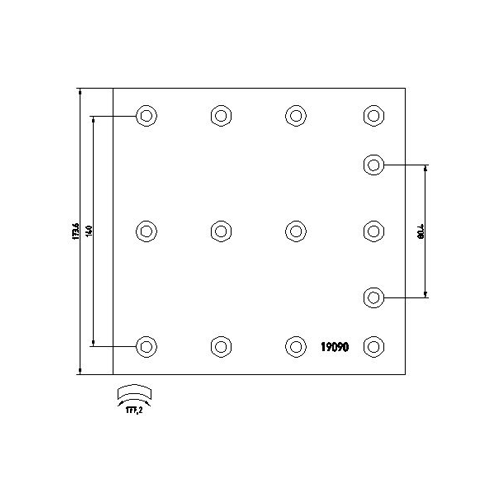

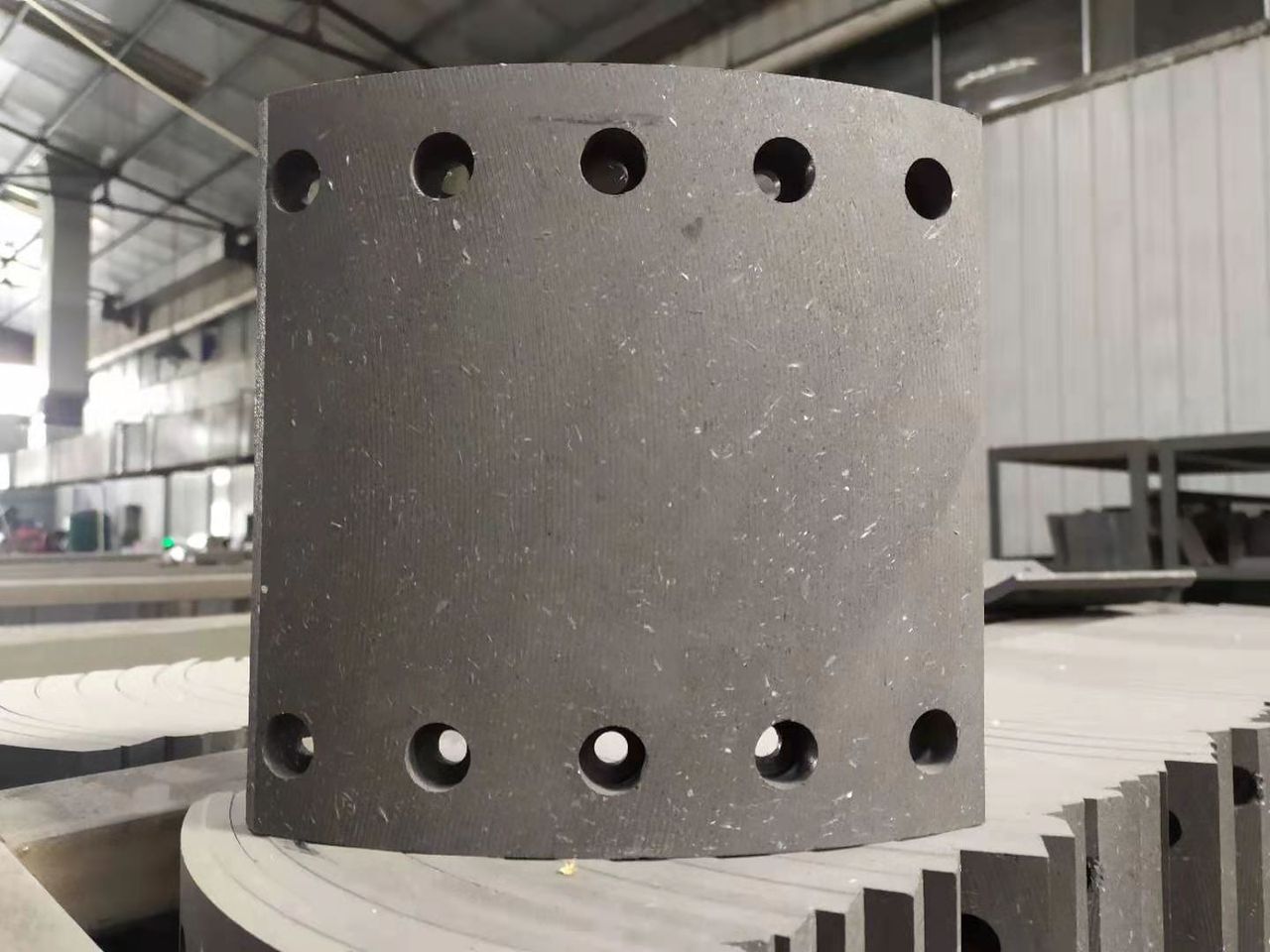

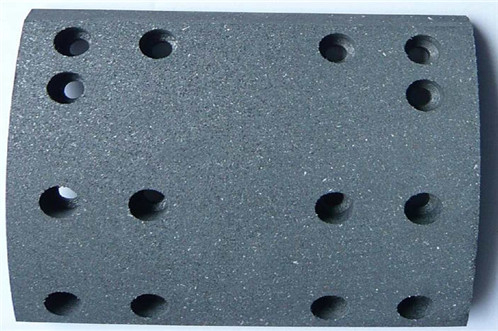

Item No: 19938 brake block / WVA 19090

OE No: 315.1686.0

BMFC No: VL/87/1; VL/87/2

Dimension (inner arc length×width×thickness): 204×200×12.1/16.8

Drum Diameter: 410

Application: AWD-ERF-Bedford, Seddon-Adkinson,VOLVO

VOLVO F 10 F / F 12 F / F 16 F / FH 12 FH / FH 16 FH / FL 7 FL / FL 10 FL / FM 12 FM

Brake lining classification:

1. Asbestos Brake linings

As the name implies, the asbestos Brake lining is the Brake lining of the asbestos component (the asbestos component accounts for 40%-60%). Because of its low cost and light weight, many vehicle production companies still use asbestos Brake linings when producing cars such as trucks and construction vehicles. Because Brake linings will collide with dust during work, and release harmful substances to pollute the environment, many countries in the world have now banned the use of asbestos products.

2. semi-metal Brake linings

The“semi-metal”hybrid Brake lining (Semi-met) is primarily made of rough steel wool as a reinforcing fiber and an important mixture. From the appearance (fine fibers and particles), it is convenient to distinguish between asbestos-type and asbestos-free organic Brake linings (NAO), and they have a certain magnetic property. His primary strengths are its temperature control capability and high braking temperature. The poor heat transfer function of the asbestos type is compared with the cooling capacity of the brake disc and the brake drum. They assist the brake disc and brake when braking. The drum emits heat from its exterior and heat is transferred to the Brake linings or brake calipers and their components. The composition of the material generally contains about 30% to 50% of iron metal materials (such as steel fiber, reduced iron powder, foamed iron powder). The semi-metallic conflict data was named after it. It is the first asbestos-free material developed to replace asbestos. Its characteristics: good heat resistance, high absorption power per unit area, large thermal conductivity, can be applied to the braking conditions of cars in high-speed, heavy-duty operation. However, it has defects such as large braking noise and brittle corners.

3. Less metal Brake linings (copper fiber Brake linings )

In a broad sense, the conflicting data in the metal Brake linings contains two or more kinds of fibers, and the Brake linings are made by mixing and pressing the inorganic fibers with a few organic fibers. He has the strength of a semi-metallic Brake lining and the brake noise is relatively small.

4. carbon fiber, ceramic Brake linings

The ceramic Brake lining is driven from the principle of cermet instead of non-metal ceramic. When the Brake lining is braked at high speed, the temperature of the brake is high. According to the measurement, it can reach 800-900 degrees, and some even higher. At this high temperature, the surface of the brake pad will have a similar response to the cermet sintering, which gives the Brake lining excellent stability at this temperature. However, the traditional Brake lining does not have a sintering reaction at this temperature, because the sharp rise in the external temperature causes the surface material to melt and even the air cushion, which causes the brake function to be drastically reduced after the continuous brake or the brake is completely lost.

There are three general conditions regarding the emergency braking of a car:

1, the front wheel first locks and drags, then the rear wheel is locked and dragged.

2, the rear wheel first locks and drags, then the front wheel is locked and dragged.

3, the front and rear wheels are locked together and dragged.

Facts have proved that the front and rear wheels are prematurely locked, which greatly reduces the problem of vehicle braking deceleration and causing side slip (I will not specifically mention here). Therefore, each manufacturer has a specification when adjusting the brakes: It is necessary to lock the front and rear wheels together.

Therefore, under normal conditions, the front wheel shoe will be replaced 2 to 3 times, and the rear wheel shoe will be replaced once.

If the wear of the rear wheel is faster than the front wheel, consciously check the braking ability of the front wheel and the disk surface. Your brake system must have problems. In the case of tight braking, it is also more prone to tail and side slip.

The front wheel shoe replacement speed exceeds this specification, and you should also automatically check your brake system, but the main points are placed on the rear wheel. Otherwise, under the condition of tight braking, it is easier to lose control and allow for seriousness.

Tip:

The main points are the front and rear wheel pumps, the gap between the front and rear shoe and the brake disc, and the exhaust condition of the front and rear wheel brake pipes, and even whether the ABS pump has residual air.