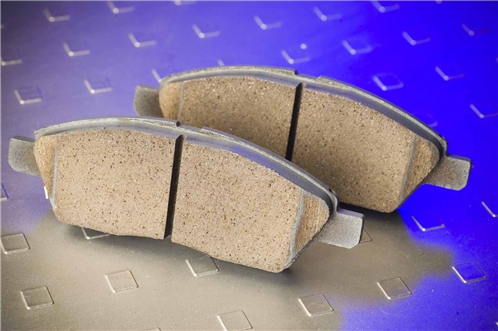

Brake Pads 29174

Brand FEIROEN

Product origin CHINA

Delivery time 35days

Supply capacity As your request

1. High quality assurance with EMARK certification.

2. OE quality braking compliant, bringing added safety and reliability.

3. Excellent stopping power

4. Extended pad and rotor life

5. Low noise

6. Consistent braking effort and pedal feel.

7. Wire mesh & adhesive layer provide secure attachment to backing plate.

8. Steel backing plate with corrosion resistant coating.

9. Installation hardware include in every kit.

10. Visual wear slot indicates when brake pads need to be replace.

Product: 29174 Auto top brake pads for Renault,VOLVO

Material: Low metalic, NAO, 100% non-asbestos

Dimension: 249.6*106.9*29.2

Application:RENAULT TRUCKS New Magnum, New Premium / VOLVO FE-Series, FH-Series, FH 16-Series, FM-Series

Certification: ISO14001:2015, OHSAS18001:2007, IATF16949:2016

Color: black/gray/green

With Accessories

Standard Export Package: Plastic Bag Shrink+Neutral/brand box (white, Feiroen box or customer's color box)+ Pallet

What is ceramic material

Automobile ceramic brake pads are a kind of brake pads. Many consumers initially mistakenly think that they are made of ceramics. In fact, ceramic brake pads are based on the principle of cermet rather than non-cermet. When the brake pad is braked at a high speed, a similar reaction occurs in the cermet sintering on the surface of the brake pad, so that the brake pad still has good stability at high temperature and ensures the braking effect.

Ceramic formulas include mineral fibers, aramid fibers and ceramic fibers (because steel fibers are corroded, producing noise and dust, so they cannot meet the requirements of ceramic formulations). These materials are lighter than other brake pads, but they are relatively light. The price will be higher. Ceramic-applied brake pads are cleaner and quieter, and provide excellent braking performance without abrading the pair.

Brake pad inspection items

The brake system of the vehicle plays a key role in the safety of the vehicle. A slight negligence may cause a major accident, so we need to pay more attention to the brake system of the vehicle. Under normal driving conditions, the brake pads should be inspected every 5,000 km. , not only to check the remaining thickness, but also to check the state of the brake pads, the return of the brake cylinder, and so on.

Friction material formula

The design of the friction material formulation is a very technical job. Because the formulation design is not a simple combination of experience, but a comprehensive result based on the full study of the structural properties of the friction material. A good friction material product is not only related to the design of the formula, but also the molding process, process design and equipment selection. It is necessary to talk about the practical formulation of the friction material.

The practical formula refers to a formula that can be put into production after repeated trials and verifications to meet the working conditions and usage requirements. The formula test is to find the right ratio of various material components, and obtain excellent comprehensive balance performance according to the principle of economic rationality. This requires the developer to have certain practical experience and basic theoretical level, adjust the formulation components according to their own experience and level, improve and compensate for the deficiency of each material component; improve the process performance of the organic adhesive to achieve easy operation and satisfaction The purpose of actual production needs; under the premise of not affecting or less affecting performance, try to make the added fillers reduce production costs.